Buying A New Road Bike

It's A Great Time To Shop

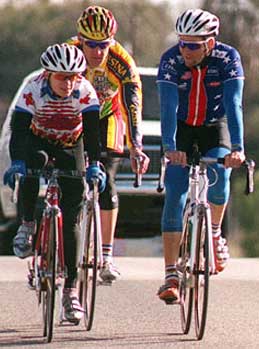

The road bike: the world's most efficient machine.

The road bike: the world's most efficient machine.You couldn't pick a better time to shop for a new road bike. Today, manufacturers offer more models than ever in a wider variety of price points. And component companies make an exceptional array of top-notch wheels, brakes and shifting systems that operate like never before. For example, it's possible to get 27-speed drivetrains that shift blink quick, and wheelsets so light pedaling is effortless. In fact, there are so many attractive choices today, that if you just walked into our store, you might be overwhelmed.

Don't be. Having a lot of choices is a wonderful thing because it drastically increases the likelihood you'll find the perfect bike -- as long as you know a little about what's available.

To help, we've put together this comprehensive guide for finding the ideal road rig. We explain the decisions you need to make and offer advice on everything from frame materials and wheels to gearing and component choice. To start, though, you need to do some self analysis (therapist not required).

Answer These Questions

Before visiting our showroom, define yourself a bit. Consider how you'll use the new bike once you get it, as well as where you'll pedal once you've had the machine for a while. And ask yourself a few questions to figure out what model's right. Are you:

Analyze Yourself

Also, consider how many miles you might log per week, or year. And think about your tendencies in purchasing other things. For example, do you consistently demand the highest quality, or are you more apt to look for reasonable quality and lower cost? Do you dig trick, high-tech gadgets or are you satisfied with simpler designs? Additionally, it helps to know about how much you want to spend because that's a quick way to focus the selection process on the appropriate models.

Answering these questions will ensure that you get the best bicycle. We'll be able to show you models with the right features for your needs, interests and budget. And you'll soon be sailing down the pavement with a big grin on your face.

Variables Of Today's Road-Bike Market

There are lots of fascinating variables in choosing a modern road bike. The rest of this article explains these choices so you'll have an easier time selecting your dream machine.

Frame And Fork Materials

Fine frames are built from a myriad of materials.

Fine frames are built from a myriad of materials.Although over the years there have been such oddities as bamboo and plastic frames, current road bikes are made of one or blends of these four materials: steel, aluminum, titanium and carbon fiber. We get into the differences below.

But first, realize that fine bicycles are built of all these materials. Also, two frames can be constructed of the same material yet have entirely different ride qualities due to differences in geometry, assembly, tube shape, and material manipulation (reinforcing a tube, for example). Which is one of the reasons it's so important to test ride and feel the bikes you're thinking of buying.

A tip for inspecting frames: Look for a tubing decal on the seattube or downtube. Sometimes manufacturers provide these and they usually explain what brand and type of material is used in the frame. We're happy to elaborate if you have questions. Just ask.

Steel

The most traditional frame material, steel has been used by framebuilders for over a century. Many types of steel tubing are available and the material is easy to bend and shape. Plus, there are myriad methods of assembly making steel very adaptable to cyclists' needs. It also offers excellent ride quality, durability, is easily repaired and affordable. If there's a knock on steel, it's that it tends to be heavy when low-quality tubing is used (found on bikes sold at department stores). And steel can rust if treated carelessly (protect that paintjob!).

Entry-level steel-frame bikes are usually less sophisticated than those typically favored by discerning cyclists and steel fanatics. But, the affordability of the lesser steel frames usually allows you to get a better level of components. And, it's possible to make a fine-riding steel frame on a budget by cutting back on some of the frills that add cost. For example, such a frame might feature less-costly TIG welding compared to the fancier lug construction on the higher-end model.

High-quality steel frames integrate great design, superior assembly, and better alloys in the tubing. A popular quality steel for bicycle frames is American SAE 4130 steel, better known as "chrome molybdenum," and referred to as "chromoly" or "chrome-moly." And, there are plenty of other impressive alloys offered by tubing suppliers such as Columbus, Reynolds, Tange and True Temper. Frames built of these materials are famous for their combination of responsiveness and comfort.

Steel is an excellent fork material. It can be formed into any shape; even aero ones. It's plenty strong. And, it also absorbs shock to soften rough roads. Steel forks are heavier than those built of lighter materials such as aluminum and carbon fiber.

Aluminum

Aluminum was first used in frame construction in 1895. But, it didn't come into wide use until the 1980s when large-diameter tubing was conceived and construction processes were perfected. Now, it's the most popular of frame materials. It's subject to the same variances in assembly and quality as steel. And, like steel, as you spend more, you get higher quality tubing and better construction.

The buzz about aluminum is that is has a more jarring ride than the other materials. But, while this used to be the case in its early years, it's not a problem today thanks to new aluminum alloys, tubing enhancements and improved construction techniques. These allow the frames to absorb shock better than ever while still offering the wonderfully lively ride that makes aluminum all the rage today.

This magic ride is attributed to aluminum being the lightest frame material -- even lighter than carbon and titanium. It makes aluminum frames great choices for racing and time trialing. And, unlike steel, aluminum won't rust; another advantage.

There are various types of aluminum tubing in use by manufacturers. Some common types are 6061 and 7005, numbers that refer to the alloys in the aluminum such as magnesium, silicon and zinc (pure aluminum isn't strong enough for bike use). And, there are some new superlight tubesets such as Easton Scandium. Be sure to ask if you have questions about an aluminum bike in our store and we can explain further.

Aluminum forks are generally stiff and light, and can be shaped aerodynamically. They also offer excellent compliance for comfort on rough roads.

Titanium

Titanium (also called "ti") is one of the longest lasting, strongest, and most expensive frame materials. Many cyclists and experts feel that it combines the best characteristics of all the other frame materials. It rivals aluminum in weight, is as comfortable as steel and it has a sprightly ride and electric handling that many riders swear by. The frames feel "alive," as if each pedal stroke gets a boost from an inherent springiness in the frame.

Titanium is hard on metalworking tools, requires expensive titanium welding rod and must be joined carefully in a controlled environment. Consequently, titanium frames are very expensive to produce, which explains their high purchase price.

The two common types of titanium are 3Al/2.5V and 6Al/4V. These designations refer to the amount of aluminum (Al) and vanadium (V) alloys used in the titanium. 6Al/4V is more expensive, lighter, harder to machine and stronger. But both titanium alloys are excellent; they may even be combined in a frame.

Only a few companies manufacture titanium forks and they are very expensive due to the additional costs in material and construction. Also, because extra strength is needed in the fork steerer (the upper tube), ti forks usually outweigh other high-tech tillers. These two considerations are why most ti frames come with carbon forks.

Carbon Fiber

Carbon fiber (also called "carbon" and "graphite") is a relatively new material and unique because it's not a metal. It's a fabric that's impregnated with a glue called resin that allows shaping and joining the material. Carbon frames are extremely light, stiff and durable. Its greatest advantage is that carbon can be manipulated essentially in endless ways (because builders can orient the fabric strands however they want), which means it can be fine-tuned to provide just about any ride qualities desired. It's also impervious to corrosion and can be built into beautiful shapes producing Ferrari-like looks.

Like titanium, because construction is somewhat complicated and because carbon fabric and resins are costly, carbon frames are on the high end of the cost spectrum. To describe these frames manufacturers use terms such as "high modulus" and "void free," which tells you that it's high-quality carbon fiber material and stellar construction. Sometimes, these designations appear on frame "tubing" decals. Be sure to ask if you have questions about the carbon material used in a frame.

Carbon is a popular material for forks due to its natural ability to absorb shock while offering fine handling. Although, they're not the best choice for heavy or aggressive riders, there are even all-carbon forks (weighing less than a pound). These are great if you want a superlight road bike. (Other carbon forks use steel or aluminum for the steerer.)

Choosing Gearing

Selecting the correct gearing means easy pedaling and happy knees.

Selecting the correct gearing means easy pedaling and happy knees.Regardless of what bike you choose it won't be much fun riding it if the gearing isn't appropriate for your fitness level and where and how you pedal. Fortunately, all component groups offer a variety of different gearing options. And we can also modify things if needed to suit your needs. Here's what's involved:

Chainrings and Cogs

There are sprockets on the front and back of the bike. The fronts are called "chainrings" and they're located on the crankset, the part that the pedals are attached to. The crankset comes with 2 (called a "double") or 3 chainrings (called a "triple"). Triple cranksets include a small inner chainring (sometimes called a "granny") that offers easier hill-climbing gears.

The sprockets on the rear of the bike are called "cogs," or, if you're referring to the entire cluster of gears, it's called a "cassette" or "freewheel." The cassette is attached to the rear wheel to drive it as you pedal. Depending on the components on the bike, there will be from 8 to 10 cogs on the rear cassette.

How Many Gears?

To figure out how many total gears are on a bike, simply multiply the number of chainrings by the number of cassette cogs. For example on a model with a triple crankset and a 10-cog cassette, you have 30 gears -- quite an upgrade from the 10-speeds so popular years ago.

How many gears to get depends on how and where you ride. If you're reasonably fit and bike in flat to rolling terrain, you'll probably be fine with a double chainring and 8 to 10 rear cogs. If it's hilly and you're getting into shape, consider a triple chainring and its easier gears.

When considering how many rear cogs to get, keep in mind that you'll have plenty of gears even if you get an 8-cog cassette. If you go to more cogs, you can either get a wider range of gears or more-closely spaced gears. The latter is excellent for racing and training because it makes it easier to fine-tune pedaling effort. Wider gearing offers easier low gears so it's ideal for mountainous riding and for when you're not in tip-top shape.

How the Gears Feel

To figure out how easy it is to pedal the gears, you have to know a little more about the chainrings and cogs. They are referred to by the number of teeth on them. So, you might read in bike specifications about 39/53 chainrings and 12-23 cassettes. This means that the small chainring has 39 teeth and the large has 53 teeth and that the cassette has a small cog with 12 teeth on it and a large one with 23. To know the size of every cog, you usually have to count each one (usually cogs and chainrings are marked, but, the marks can be hard to see).

Know Your Numbers

Don't let the numbers confuse you. The key thing to know is that for chainrings, larger numbers mean it's harder to pedal and vice versa. For cogs, it's the opposite: the larger the number, the easier it is to pedal and vice versa. By keeping these rules in mind, you can quickly see that a 30/42/52 triple crankset and a 12-30 cassette will offer much easier gearing than a 39/53 double with a 12-23 cassette.

Pondering a Triple

Many people wonder whether or not they need a triple crankset. Our advice is that it depends a lot on how and where you ride. If you like the hills, ride fairly long distances, sometimes carry gear and aren't training all the time to be in optimum fitness, a triple is a great thing to have. Even if you don't use the small chainring all that much, it can be a lifesaver at the end of a long ride when a tough climb stands between you and home.

Even some competitive riders favor triples, though if you're really strong, you may decide to forgo the additional grams of a third ring. Also, a triple-chainring drivetrain shifts slightly more slowly than a double, which is a consideration in a race when a slow shift can cost you a podium spot.

If you're not sure which is right for you, we recommend coming in and trying a triple to feel how it works for you.

Cassette Considerations

You also need to decide on the range of gears on your rear cassette. Here's a guide to some commonly available sizes and what they're designed for:

| cassette | what it's good for |

| 11-21 | stronger/competitive riders on flat courses |

| 12-23 | stronger/competitive riders on varied terrain |

| 12-25 | a combination that begins to favor climbing |

| 12-27 | offers significantly easier climbing gears |

Wheels And Tires

Modern wonder wheels are veritable wings for your bike.

Modern wonder wheels are veritable wings for your bike.Not too long ago, when you bought a new road bike, you got fairly run-of-the-mill wheels comprised of decent rims, spokes and hubs. These wheels were reliable and worked just fine. But, they didn't really add any pizzazz to your new two-wheeler.

All that has changed. Today, many if not most road bikes feature wheels that are marvels of engineering. They're prettier, more aerodynamic, durable and lightweight, sometimes superlight. Why is this important, you ask?

Because when you cut wheel weight, you drastically improve a bike's climbing, acceleration and handling. This happens because wheels are rotating weight. And this type of heft is felt most by the rider. In fact, a few-hundred grams reduction at the wheels feels more like a few pounds reduction. On the road, it's an amazing feeling, like suddenly dropping 10 pounds of body weight.

Box vs. Aero Section Rims

One difference in these new wheels is rim type. There are two basic designs named after their cross sections: conventional box-section rims (square or rectagonally shaped) and aero-section rims (triangularly shaped).

Box-section rims are lightweight, accelerate quickly, and provide the most comfort. Aero-shaped rims are stronger, have less wind drag, and are stiffer (less comfortable). It's important to consider wheel feel when you're test riding bikes. You might prefer one type to another.

When choosing a rim or wheel type it's important to consider where and how you ride, as well as how much you weigh. For example, a 140-pound rider who spins leisurely mostly on rough pavement, will probably prefer a box-section rim for its additional comfort. But, a competitive 200 pounder on smooth roads will much prefer the stiffness and speed of aero-section hoops.

There are many wheelsets on the market designed for general and specific types of riding. Most use minimal spoke counts (traditional wheels have 32 spokes), which cuts wind drag and wheel weight. Superlight wheels are excellent for climbing. Aero wheels are usually a little heavier and intended to cheat the wind for an advantage during long rides and time trials.

Tire Talk

Bike companies use a variety of different tires on their road models and usually, the tires are good for 1,000 to 2,000 miles, depending on your weight, riding style, and whether the tire is located on the front or back. So, the chances are pretty good that you'll be fine riding on the tires that come stock on your new bicycle.

You might consider upgrading however, if the tires are the wrong size or design for your predominant type of riding. One important difference is bead type. Beads are found in both edges of the tire. They're the parts that grip the rim to hold the tire on the wheel. Less-expensive tires use wire beads, which add weight (remember that rotating weight is the most important kind). Better models have Kevlar (a super-tough fabric) beads.

Tires with Kevlar beads are called "folding tires," and they're a great upgrade if you want lightweight wheels and lively handling. These tires cost more, so expect to pay for them. But, the additional expense is worth it if you want optimum performance.

Another reason to swap tires is to get a different width. Tire width determines how much air it holds, which in turn decides ride softness. It also affects how the bike handles, rolling resistance and durability.

You'll find the tire's size written on its sidewall as "700 x XX," where XX is the tire's width in millimeters (700 refers to the nominal outside tire diameter in millimeters, a European standard called "700c"). We're happy to discuss tire differences with you. Here's how the sizes compare:

| size | what it's good for |

| 700 x 20 | thin, primarily for time trials and lighter riders |

| 700 x 23 | normal, for most conditions, racing and training |

| 700 x 25 | thicker, longer wearing, more shock absorption |

| 700 x 28 | thick, longest lasting, ideal for touring, commuting, heavier riders |

About 650c Wheels

Some time-trial bikes, as well as some compact, smaller models come equipped with 650c wheels, which are smaller diameter than 700s. These are a little lighter and slightly stronger, and they accelerate faster than standard 700 wheels. But, 650c wheels sometimes ride a bit rougher (smaller, lighter riders can compensate by dropping tire pressure slightly), lose momentum a bit faster and cover less distance per revolution (strong riders will require taller gearing). So, if you're comparing bikes with both wheel sizes, be sure to test ride them to feel for yourself the differences. That's the best way to decide.

Component Groups

30 gears. Foolproof bearings. Awesome braking.

30 gears. Foolproof bearings. Awesome braking.Today's componentry will amaze you!

The two companies selling road groups are Shimano and Campagnolo and each offers 5 different levels of components. A group is comprised of brakes, hubs, chain, cassette, bottom bracket, crank, derailleurs, shifters and headset (sometimes a seatpost is included, too).

As you spend more money, parts get lighter and bearing quality (bearings are what the hubs, headset, pedals and crankset spin on) improves. Higher-level components shift and brake slightly better, too -- though even entry-level braking and shifting is exceptional on modern systems.

So, how do you decide what to buy? It comes down to your price range and which group offers the features you want (i.e. weight, number of gears, appearance, quality). Usually, you can narrow it down to a couple of groups. And, at that point, a great way to decide is to ride and compare. If you can feel a difference in braking and shifting, go with the bike you like better.

To help you understand what's what with modern parts packages, here's an overview:

| Level | Brand | Group | Drivetrain | Comments |

| entry-level | Campagnolo | Mirage | double or triple w/9 cogs | fine function; some steel parts |

| enthusiast-level | Campagnolo | Veloce | double or triple w/9 cogs | nice function; less steel; better finish |

| serious-level | Campagnolo | Daytona | double or triple w/9 or 10 cogs | most affordable 10-speed group |

| race-level | Campagnolo | Chorus | double or triple w/9 or 10 cogs | almost Record quality and finish |

| pro-level | Campagnolo | Record | double or triple w/9 or 10 cogs | world's lightest group |

| entry-level | Shimano | Sora | double or triple w/8 cogs | some steel; shifts and brakes great |

| enthusiast-level | Shimano | Tiagra | double or triple w/9 cogs | less steel; more interchangeability |

| serious-level | Shimano | 105 | double or triple w/9 cogs | great price; hollow crankarms |

| race-level | Shimano | Ultegra 600 | double or triple w/9 cogs | almost D-A quality; hollow arms |

| pro-level | Shimano | Dura-Ace | double or triple w/9 cogs | Lance's group; superlight |

Shopping Tips

We're looking forward to helping you select the perfect road bike.

We're looking forward to helping you select the perfect road bike.Price Particulars

We've asked you to think about what you'd like in a bike and what you'd be comfortable spending. Now that you have an idea how to decide what type of road machine to get, it's time to come into our store and do some tire kicking and test riding to see how the models compare in person. This will complete the picture and give you a chance to see what you get at the various price points. Here are a final few helpful tips:

Shopping Guidelines

You're Ready To Come In And Look At Some Bikes!

We're sure you'll enjoy your shopping experience with us. Come in today to check out our selection of road bikes and get to know our professional staff!